Improving Efficiency with Automated Cutting Solutions

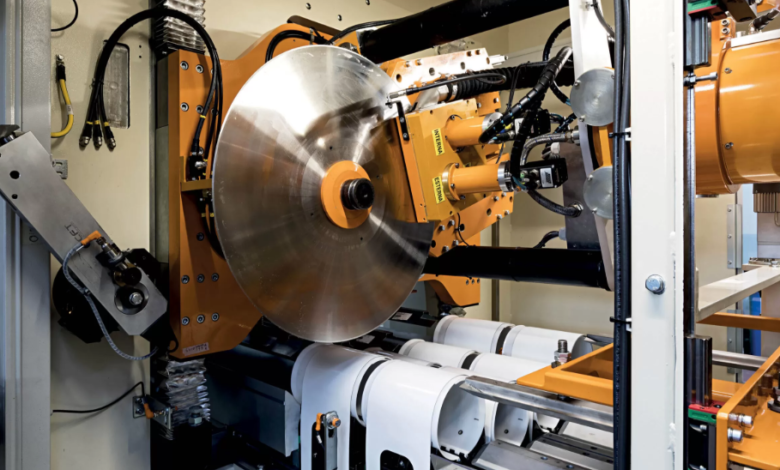

Manufacturing operations face mounting pressure to reduce costs while maintaining quality standards. Automated cutting technologies have emerged as a game-changing solution, transforming how companies approach production processes across multiple industries.

These advanced systems deliver precision, speed, and consistency that manual cutting methods simply cannot match. From automotive components to aerospace parts, businesses are discovering that automation isn’t just an upgrade—it’s becoming essential for competitive survival.

The Rise of Automated Cutting Technology

Traditional cutting methods rely heavily on human operators, creating bottlenecks and inconsistencies that impact overall productivity. Modern automated systems eliminate these limitations by combining sophisticated software with precision machinery.

Computer Numerical Control (CNC) machines, laser cutters, and plasma systems now integrate seamlessly with production management software. This integration allows for real-time monitoring, quality control, and immediate adjustments when specifications change.

The technology has evolved far beyond simple programmed cuts. Advanced systems now feature artificial intelligence that learns from each operation, optimizing cutting paths and reducing material waste with each cycle.

Key Efficiency Benefits

Enhanced Speed and Throughput

Automated cutting systems operate continuously without fatigue, dramatically increasing production capacity. Where manual operators might complete 50 cuts per hour, automated systems can perform 200 or more with identical precision.

These systems also eliminate setup time between different cutting patterns. A single machine can switch from cutting circles to complex geometric shapes in seconds, not minutes or hours.

Superior Precision and Quality

Human error becomes virtually eliminated when machines handle cutting operations. Automated systems maintain tolerances within thousandths of an inch, ensuring every piece meets exact specifications.

This consistency reduces downstream quality issues, minimizing rework and customer complaints. Products fit together perfectly during assembly, streamlining the entire manufacturing process.

Reduced Material Waste

Smart nesting software optimizes material usage by calculating the most efficient cutting patterns. These algorithms can reduce waste by 15-30% compared to manual layout methods.

The software considers material grain direction, structural requirements, and cutting tool paths simultaneously. This comprehensive approach maximizes yield from every sheet, bar, or roll of raw material.

See also: Maximizing Digital Marketing Performance With Technology 3509586898

Industry Applications and Success Stories

Automotive Manufacturing

Car manufacturers have embraced automated cutting for both prototype development and mass production. Sheet metal components, gaskets, and interior trim pieces benefit from the speed and accuracy these systems provide.

One major automotive supplier reported a 40% reduction in production time after implementing automated cutting solutions. Quality defects dropped by 65%, significantly improving customer satisfaction ratings.

Aerospace and Defense

Precision requirements in aerospace applications make automated cutting virtually mandatory. Complex titanium and aluminum components demand tolerances that only automated systems can consistently achieve.

The ability to maintain detailed records of cutting parameters also supports the strict documentation requirements common in aerospace manufacturing.

Textile and Apparel

Fashion and textile industries use automated cutting to handle high-volume orders with quick turnaround times. Pattern changes that once required hours of manual adjustment now happen with simple software updates.

Companies offering specialized wire cutting services have found particular success in technical textiles, where precise dimensions are critical for performance applications.

Cost-Benefit Analysis

Initial Investment Considerations

Automated cutting systems require significant upfront capital, typically ranging from $50,000 to over $500,000 depending on capabilities and size. However, most companies recover this investment within 18-24 months through efficiency gains.

Financing options and leasing programs make these systems accessible to smaller manufacturers who might otherwise be unable to afford the technology.

Operational Cost Savings

Labor costs decrease substantially as fewer operators are needed to achieve higher output. Energy efficiency improvements also reduce utility expenses, as modern systems use power more effectively than older equipment.

Maintenance costs remain predictable with proper preventive care programs. Many manufacturers find their total operating costs decrease by 20-35% within the first year of implementation.

Return on Investment Metrics

Beyond direct cost savings, automated cutting systems provide measurable improvements in delivery times, customer satisfaction, and market competitiveness. Companies often discover new business opportunities that weren’t feasible with manual processes.

The ability to handle rush orders and customize products without significant cost increases creates additional revenue streams that further justify the investment.

Making the Transition to Efficiency

Implementing automated cutting solutions requires careful planning and consideration of existing workflows. Companies achieve the best results when they view automation as a comprehensive upgrade rather than simply replacing individual machines.

Staff training and process redesign often prove as important as the technology itself. Operators transition from manual cutting to system programming and quality monitoring, requiring new skills but often finding the work more engaging and less physically demanding.

The manufacturing landscape continues evolving toward greater automation and efficiency. Companies that embrace these changes position themselves for sustained growth, while those that resist may find themselves struggling to compete. Automated cutting solutions represent a proven path toward operational excellence and long-term success.