Why Acoustic Barriers Are Transforming Noise Control in Modern Applications

Introduction: The Growing Challenge of Noise

Noise pollution is no longer just an urban problem—it impacts workplaces, homes, and even vehicles. From loud machinery to household appliances, unwanted sound affects comfort, productivity, and health. This is why acoustic barriers have become essential. These advanced barrier products are designed to block, absorb, and dampen sound waves while also minimizing vibration.

Unlike traditional insulation, acoustic barriers combine flexibility, durability, and thermal resistance, making them suitable for industries ranging from automotive to construction.

What Makes Acoustic Barriers Different From Standard Insulation?

Standard insulation materials focus on temperature regulation, but acoustic barriers are engineered to stop airborne sound and reduce impact noise. They also act as anti-vibration pads, preventing the buzzing and rattling common in industrial equipment.

Some unique characteristics include:

- Ability to conform to flat, curved, or uneven surfaces

- Compatibility with acoustic foams to create laminated solutions

- Excellent resistance to heat and thermal radiation

- Designed to prevent transmission loss across multiple frequencies

These properties make acoustic barriers a versatile solution for diverse environments where both noise and vibration control are required.

Key Applications of Barrier Products Across Industries

Automotive and Transportation

Vehicle manufacturers rely heavily on acoustic barriers to reduce engine noise, road vibrations, and cabin echoes. By applying barrier products in panels, floors, and engine bays, they improve passenger comfort and meet noise regulations.

Household Appliances

Washing machines, dishwashers, and refrigerators all use acoustic barriers to cut down on operational noise. This ensures quieter homes without compromising performance.

Heavy Machinery and Agricultural Vehicles

Operators of tractors, excavators, and earth-moving equipment benefit from reduced vibration and sound levels, which enhances safety and concentration during long shifts.

Construction and Building

From insulating steel sinks to soundproofing lift cabins, acoustic barriers play a role in making buildings more comfortable and efficient. They’re also integrated into pipe insulation to reduce vibration and sound transmission.

Marine and Aerospace

In yachts, ships, and aircraft, acoustic barriers provide both soundproofing and thermal insulation, especially in high-heat areas like engine rooms.

See also: Small Home, Big Style: Space-Saving Design Trends

Exploring Different Types of Acoustic Barrier Products

Polymeric Acoustic Barriers

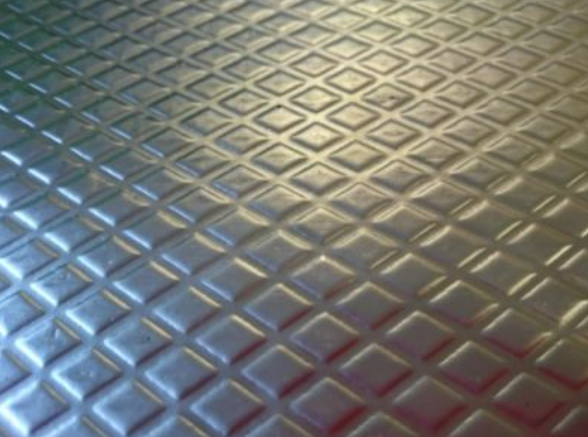

Products such as C03 (1.4mm) and C09 (2.5mm) are vinyl-based membranes loaded with natural fillers. They are lightweight yet effective, ideal for enhancing the insulation of wood, metal, or plastic panels. Their strength lies in tackling the coincidence dip resonance problem found in stiff, lightweight materials.

Bitumen PE Foil Acoustic Barriers

Models like C022 and C023 use self-adhesive bitumen with PE foil facing. They excel at creating clean, vibration-resistant flat surfaces and allow easy bonding with substrates.

Bitumen Aluminium Acoustic Barriers

C024 barriers combine bitumen, polymers, and mineral fillers protected by aluminium foil. They withstand heat and vibration, making them suitable for engines in cars, construction machinery, and marine vehicles.

How Foam Conversion Enhances Acoustic Barriers

To tackle more complex soundproofing issues, acoustic barriers are often combined with foams in a process known as foam conversion. This involves shaping, laminating, or molding foam into specific configurations.

Foam Types Used With Barriers:

- Polyurethane foam – For seating, cushions, and insulation

- Polystyrene foam – Lightweight and insulating

- Polyethylene foam – Durable, moisture-resistant, used in industrial padding

By merging foams with acoustic barriers, manufacturers create bespoke solutions—such as insulating the engine room of a yacht or reducing radiator noise in construction vehicles.

Benefits of Acoustic Barriers You Should Know

- Noise Reduction at the Source – Controls both airborne and impact sound effectively.

- Improved Safety and Compliance – Helps workplaces meet occupational noise limits.

- Enhanced Comfort – Creates quieter cars, homes, and offices.

- Durability in Harsh Environments – Withstands vibration, heat, and long-term use.

- Customizable Solutions – Can be supplied in sheets, cut-to-size panels, or laminated composites.

When Should You Choose Acoustic Barriers Over Other Solutions?

While acoustic foams are great for controlling echoes inside a room, acoustic barriers are the right choice when:

- Noise is coming through walls, panels, or enclosures

- Vibrations are causing structural noise problems

- Environments involve high heat alongside noise control needs

- A durable, long-term solution is required for industrial or heavy-duty applications

Industries Leading the Adoption of Barrier Products

- Construction Sector – Office buildings, apartments, and lifts are increasingly using acoustic barriers.

- Transportation – Automotive, aerospace, and marine industries rely on barriers for cabin comfort.

- Household Goods – White goods manufacturers use barriers to meet consumer demand for quieter appliances.

- Industrial & Agricultural Equipment – Protects workers from excessive machine noise.

This widespread adoption highlights the adaptability of acoustic barriers in solving modern noise challenges.

Why Are Acoustic Barriers Becoming More Important Now?

The rising importance of acoustic barriers can be linked to:

- Stricter noise regulations worldwide

- Urban population growth leading to increased exposure to noise

- Technological innovation making barriers more efficient and lightweight

- Higher consumer expectations for quieter cars, appliances, and workplaces

In short, industries can no longer ignore noise management—making barrier products an integral part of modern engineering.

Conclusion: Investing in a Quieter Future

Acoustic barriers are not just another insulation product—they are a proven solution to one of today’s biggest environmental and industrial challenges: noise pollution. By combining sound insulation, vibration damping, and heat resistance, barrier products offer a powerful way to enhance comfort, productivity, and safety across countless applications.

From automotive design to household appliances and construction projects, acoustic barriers are quietly shaping a more peaceful future. For businesses and industries looking to stay ahead, investing in these innovative products is not just an option—it’s a necessity.